BARRIQUAN: ROBOTIC DEBURRING MACHINE

RDM-S

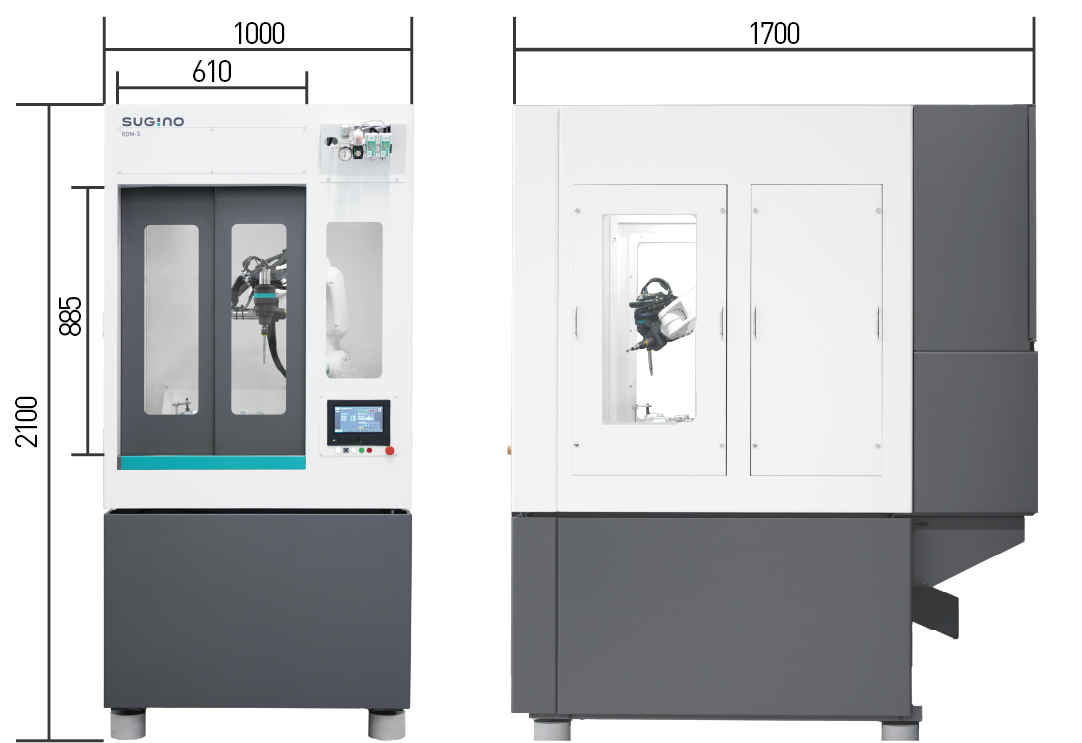

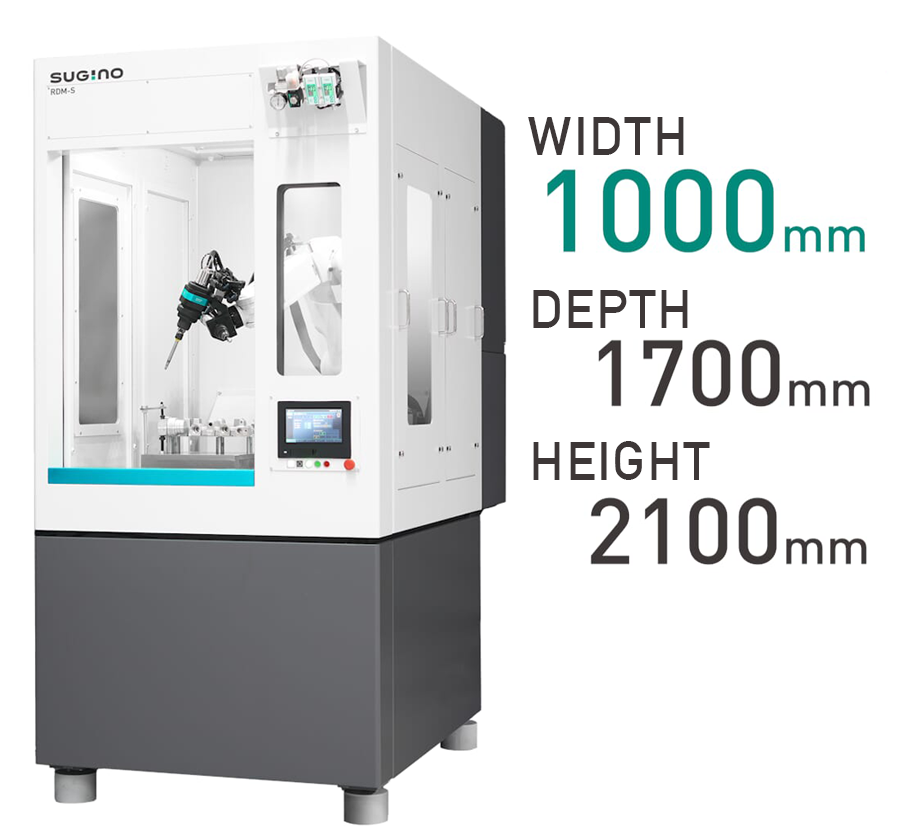

The RDM-S is a compact robot deburring cell engineered to automate the process, rather than deburring manually. It features a 7 kg payload industrial articulated robot equipped with up to two Barriquan spindle motors, which use a floating mechanism to adapt to variations in part surfaces and positional deviations. The RDM-S ensures high-speed, high-precision deburring in a space-saving footprint just 1,000 mm in width.

WHAT IS FLOAT DEBURRING?

A method to help automate deburring tasks. Learn more about this process.

FEATURES of the RDM-S

Equipped with 2 different floating mechanisms attached to one robot with a 7kg payload capacity. Twin spindles save time while allowing you to process a wide variety of workpieces.

TWIN SPINDLES FOR FLEXIBLITY AND SPEED

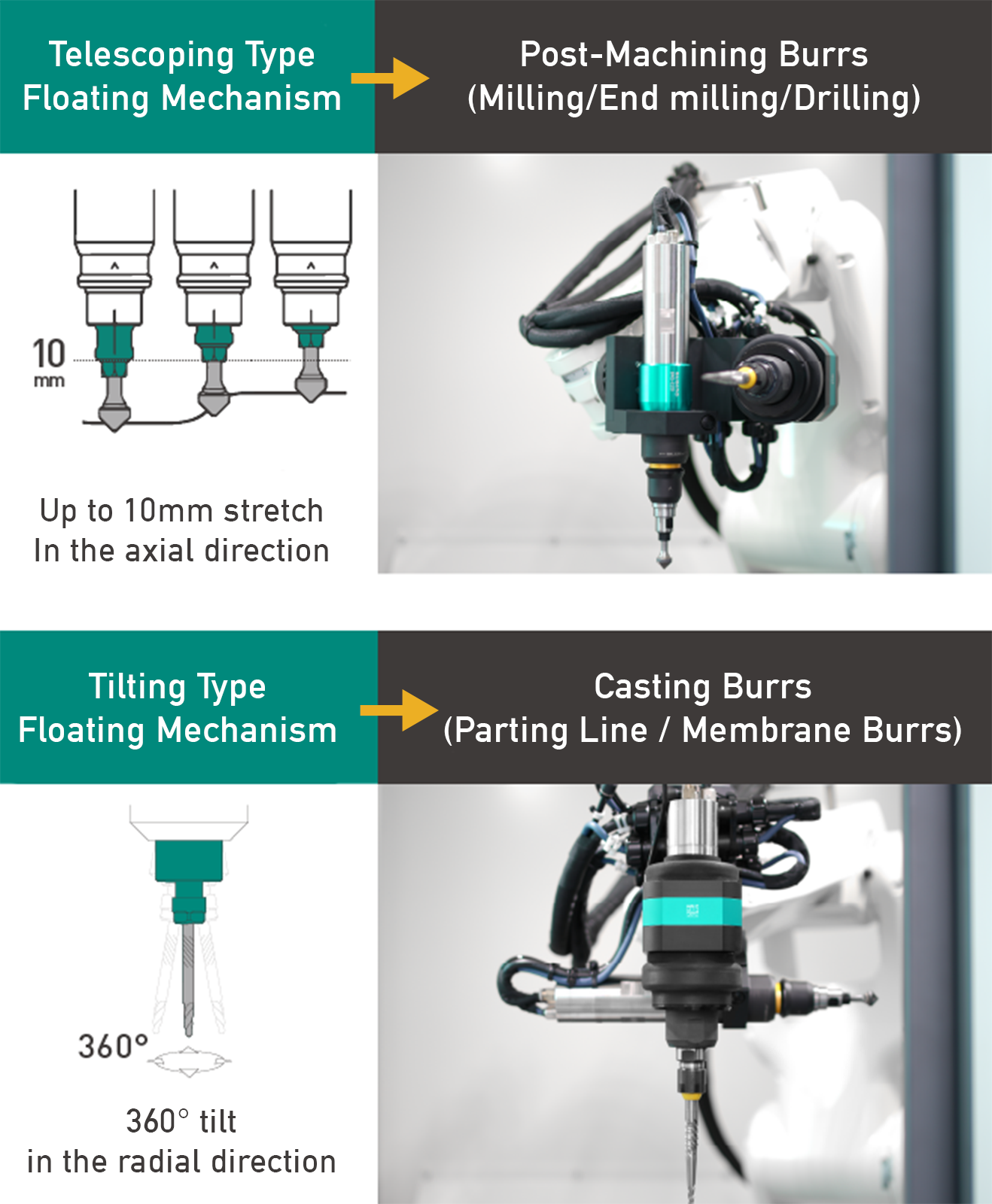

Built-in tilt floating mechanism moves freely in the radial direction 360° while tilting

High-speed tool changes

The RDM-S can change Barriquan tools just by turning the robot hand. Fast tool replacement means reduced cycle time.

Removes multiple types of burrs on edges and surfaces

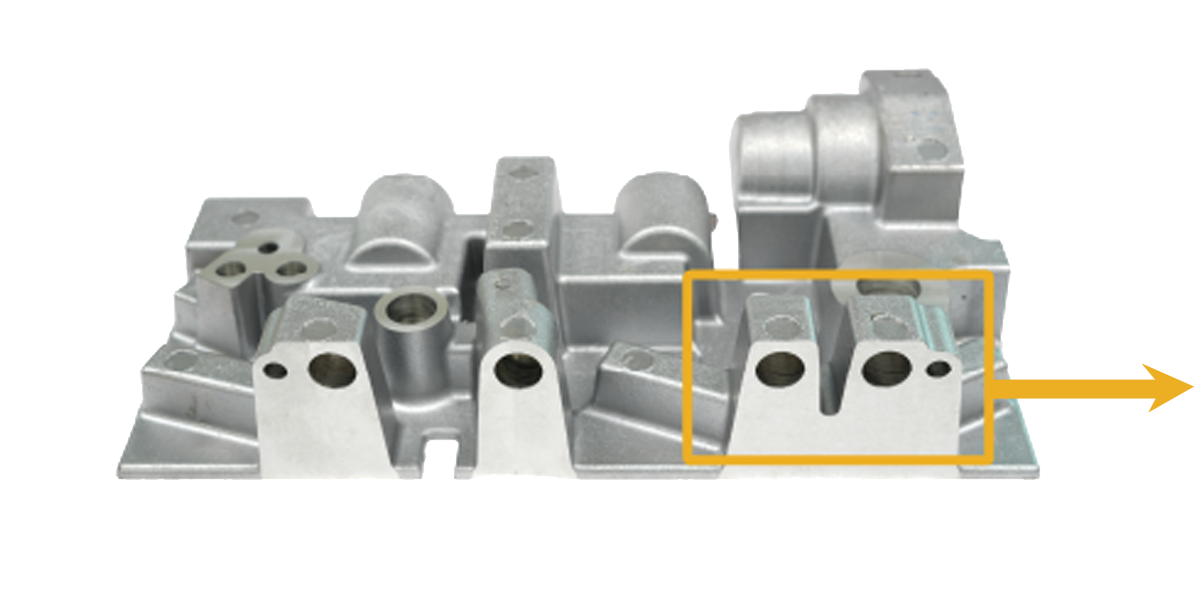

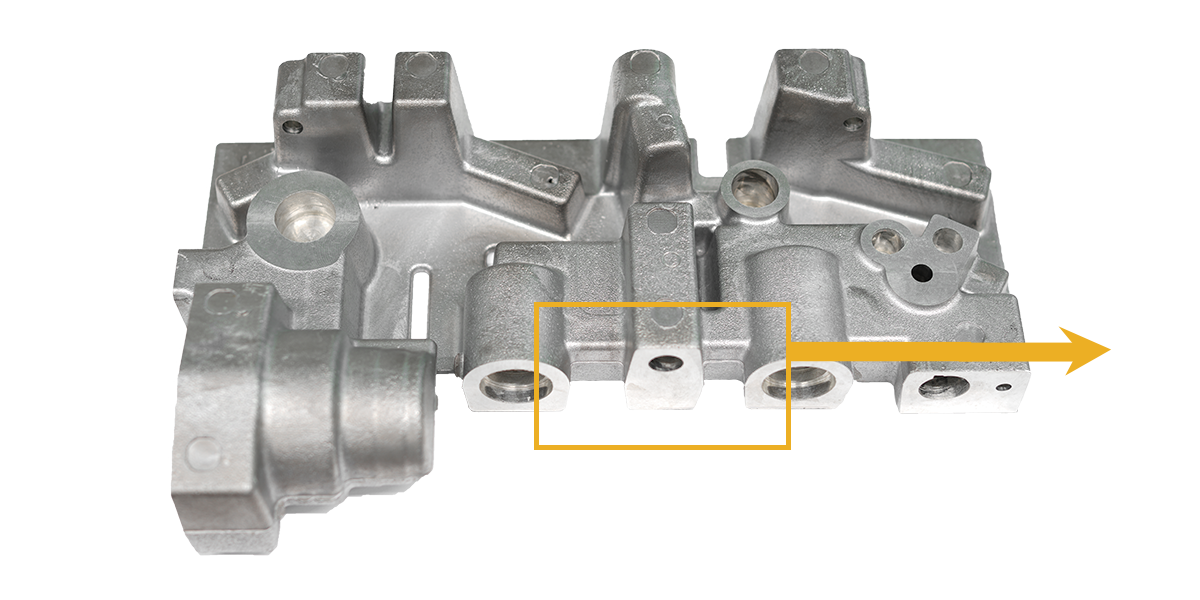

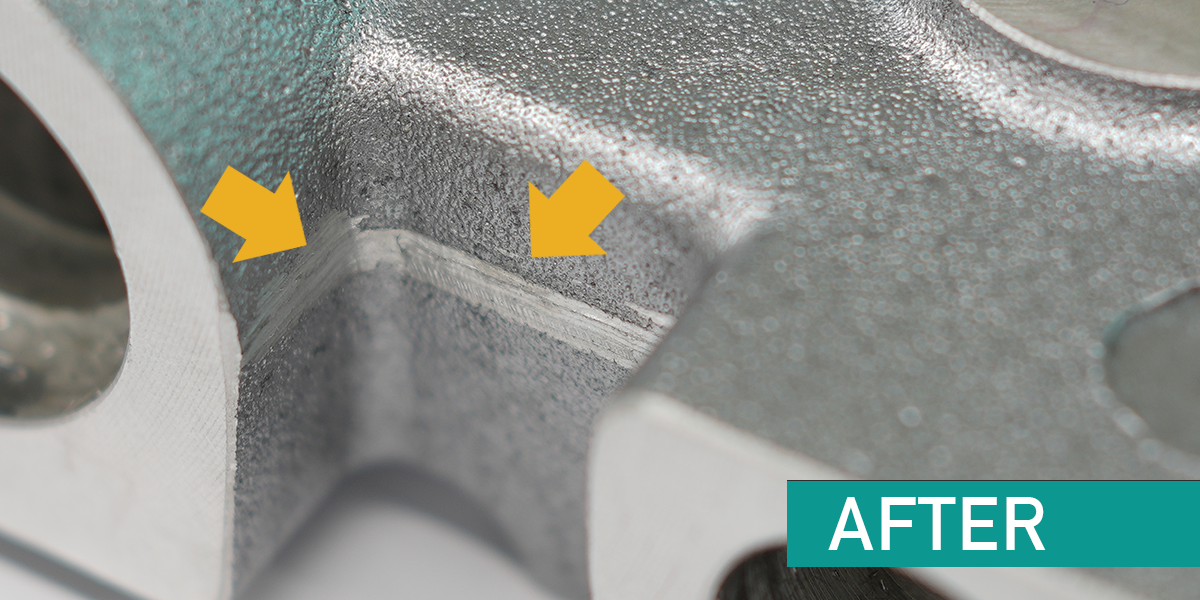

The telescopic-type BRQ-EZ01 and the tilting-type BRQ-EL02, both with a built-in floating mechanism, can be be installed. This flexibility means the RDM-S can handle post-machining deburring (from milling/end milling/drilling) and burrs from die-casting - such as parting lines or membrane burrs.

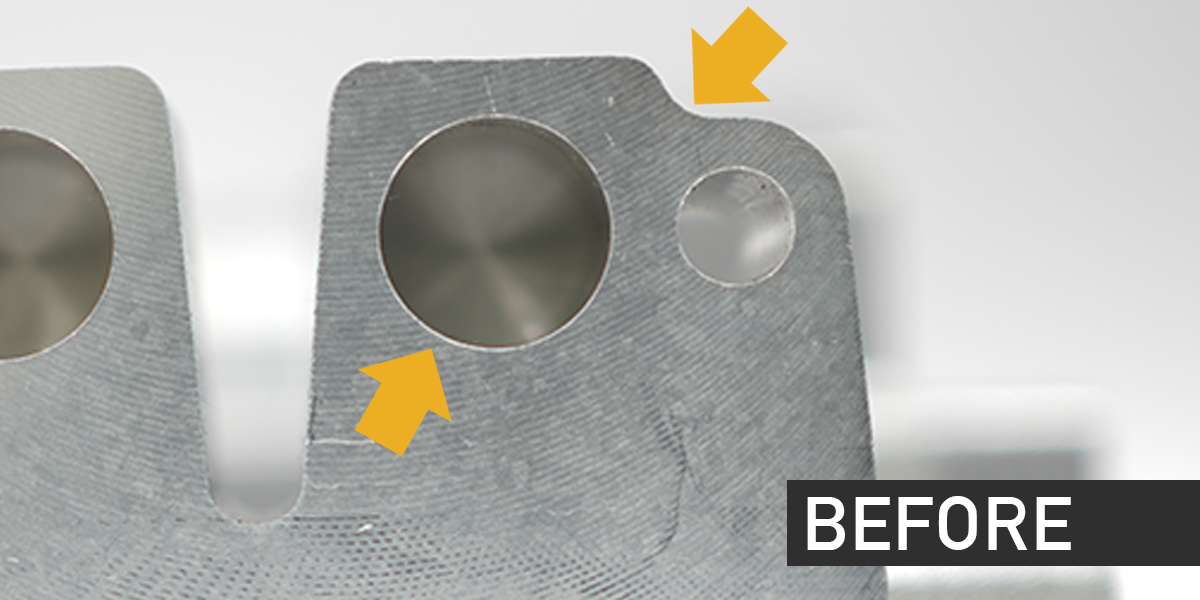

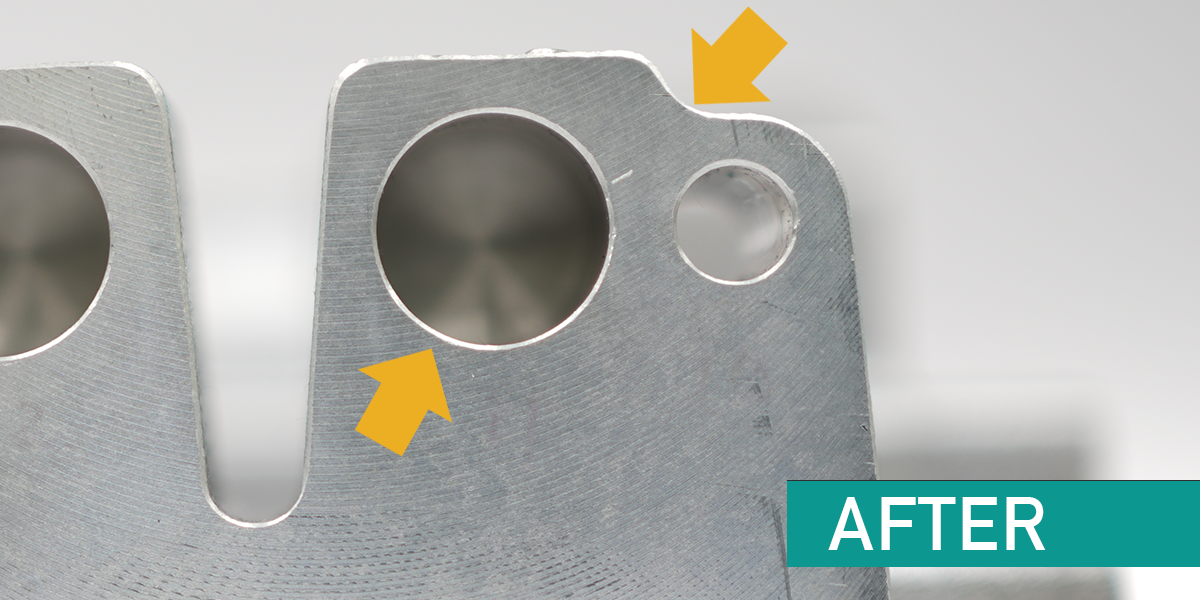

Before and After Examples

Casting Burrs

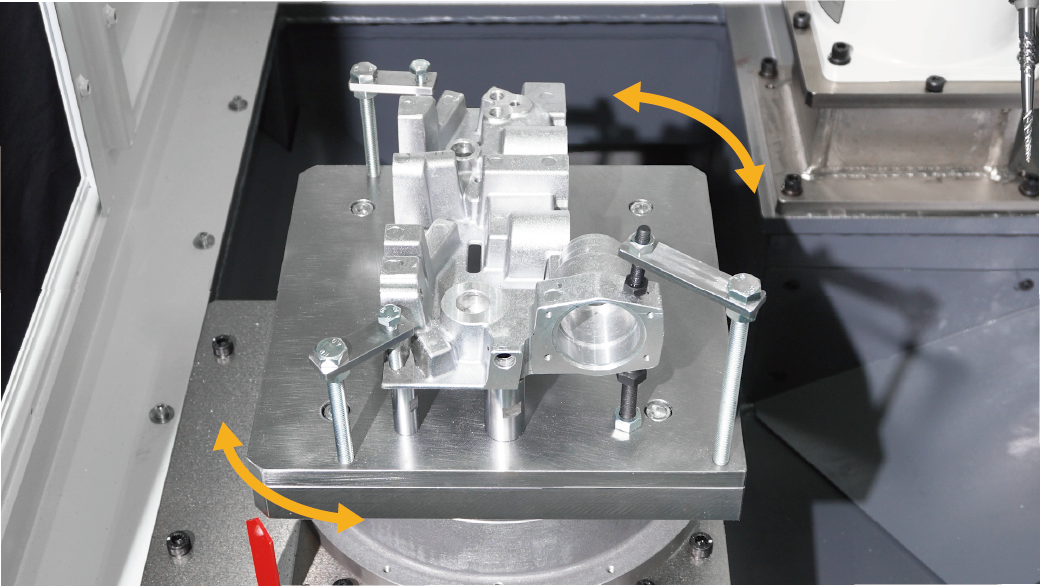

5-sided processing in a small area

The RDM-S is equipped with a standard index table of 300mm x 300mm and supports workpieces up to 250mm x 250mm. The index table works synchronously with the robot, making 5-sided processing in a small space easy.

Small size. Big impact.

The RDM-S fits easily into your existing production line - often in the same amount of space where manual deburring was already taking place.

Watch it in Action

Questions about automating

your deburring process?