As the year is wrapping up, Sugino celebrates a year filled with new solutions for precision cleaning, deburring, tooling, and surface finishing. Let’s recap 2025’s latest technology developments.

Our latest technologies were developed to help manufacturers tackle complex geometries, meet tighter tolerances, and reduce reliance on manual labor, all while improving throughput and lowering overall production costs.

Here’s a look at what’s new:

New Ways to Deburr

Reach Deburr, and Clean – Even Compound Angles

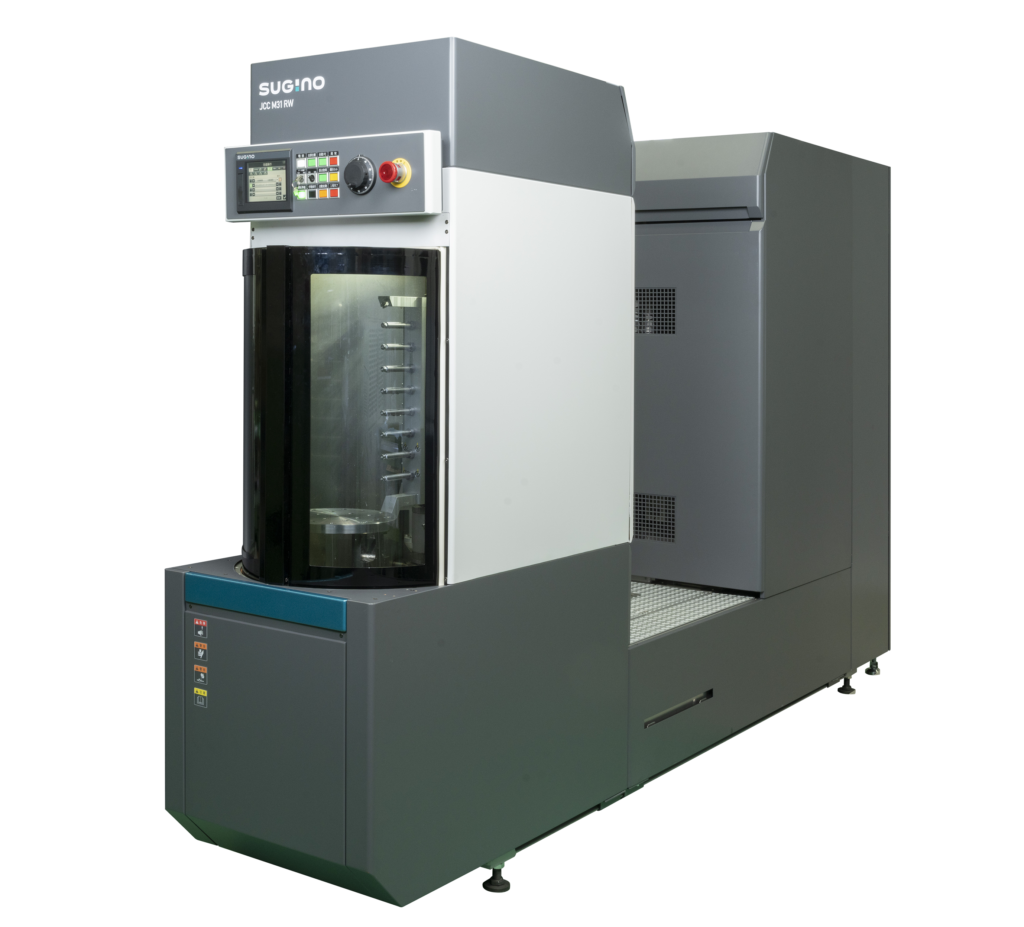

JCC 4+1 Deburring and Washing System

This versatile system enables multi-angle deburring with a newly developed hollow 2-axis tilting rotary table. Its open-bottom design ensures complex parts are finished with precision.

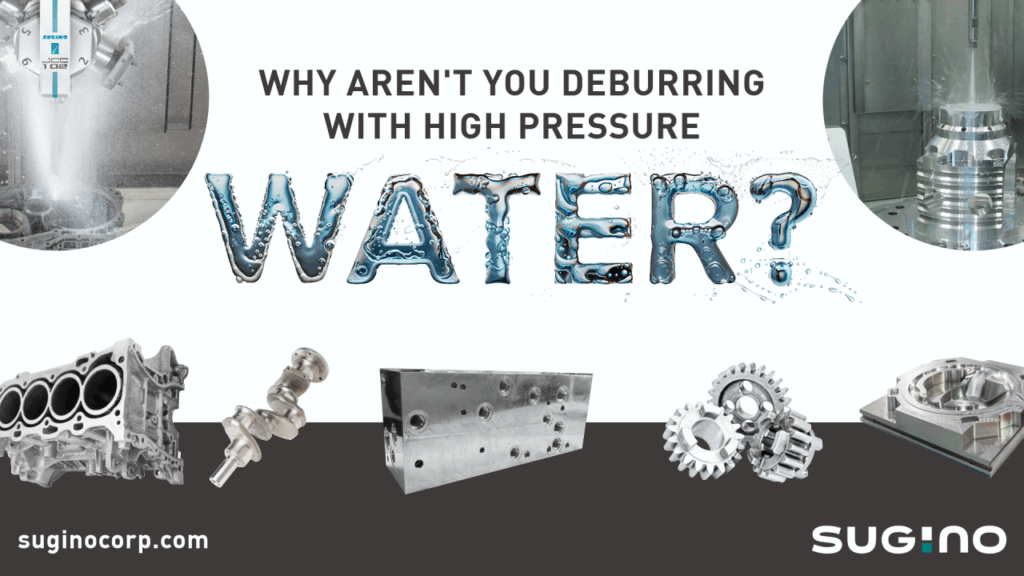

10,000 PSI for Your Toughest Deburring Challenges

Jet Deburring Machine (JDM)

Operating at 10,000 PSI and including a New Dual-Flow Nozzle and optional lance nozzle, this compact, high-pressure system removes burrs quickly and cleanly, even from intricate geometries.

Are You Ready to Stop Deburring Manually?

RDM-S

This compact robot deburring cell automates the deburring process, eliminating the need for manual deburring, in a space-saving footprint just 1,000 mm in width. Twin spindles and a standard indexing table improve production efficiency, reduce manual labor costs, and ensure consistent quality across finished products.

Want more deburring content? Have deburring questions? See what our experts have to say.

New Ways to Clean

Compact parts washing and drying units that can be easily integrated into your current production lines.

Jet Storm Washer

A fully automated parts washer that performs washing, degreasing, draining, and hot air drying, all in one compact machine. Additionally, it integrates easily into existing production lines.

JCC-Module

Add modules to expand as your needs change. This compact modular parts washer easily integrates into existing production lines, making it ideal for precision cleaning, chip & oil removal, and drying of metal components.

For more about parts washing or fluid cleaning, check out these articles:

Effectiveness of Cavitation for Peening & Surface Finishing

A recent peer-reviewed study, conducted in collaboration with the University of Washington and Sugino Machine Ltd., evaluated the effectiveness of Cavitation Abrasive Surface Finishing (CASF) in improving surface quality, reducing stress concentrations, and inducing beneficial compressive residual stresses.

The findings highlight CASF as a promising post-processing technique for titanium components manufactured using laser powder bed fusion (L-PBF).

Get the full research article here:

New Water Jet Tools & Accessories

Sugino showcased the power of high-pressure water jet technology at the WJTA Expo in New Orleans earlier this month.

Featured Technology:

- Hi-Rotary Gun – A water jet gun that sprays ultra-high-pressure water with a rotating nozzle head at high speed, for efficient cleaning and peeling.

- Aqua Selrotor – This water jet unit rotates the nozzle at high speed, utilizing the reactive force of the ultra-high-pressure water jet to clean and peel walls and flat surfaces efficiently.

- 3D Nozzle – An automatic, specialized water jet nozzle unit designed to clean polymerization vessels, reactors, spray dryers, and various other tanks.

- Safety Selector – An air-driven, ultra-high-pressure water control valve designed to improve safety for operators and worksites while working with high-pressure water jet tools.

- High-Performance Pumps – Sugino Pumps have set the standard for reliability and innovation in high-pressure and ultra-high-pressure technology.

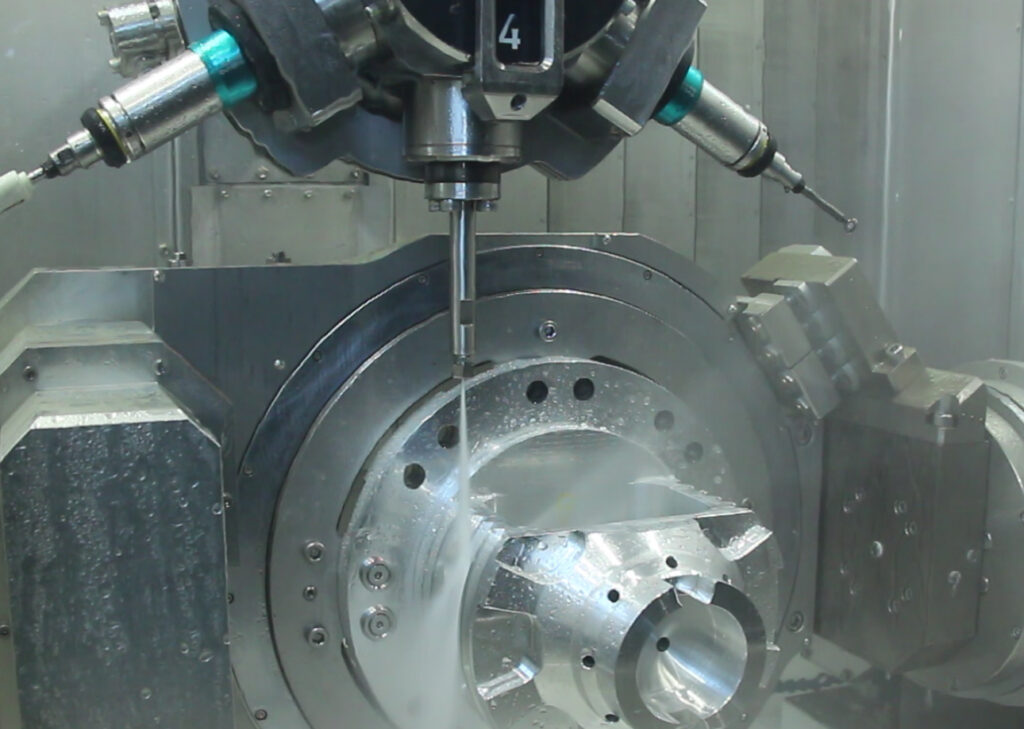

Robot Drilling & Tapping

The SELFEEDER DUO Robot Edition is a high-performance machining unit that mounts directly to an industrial robot arm for efficient multi-face machining of large workpieces. Its advanced design enables approach from virtually any angle and includes features that solve common challenges in robotic drilling and machining.

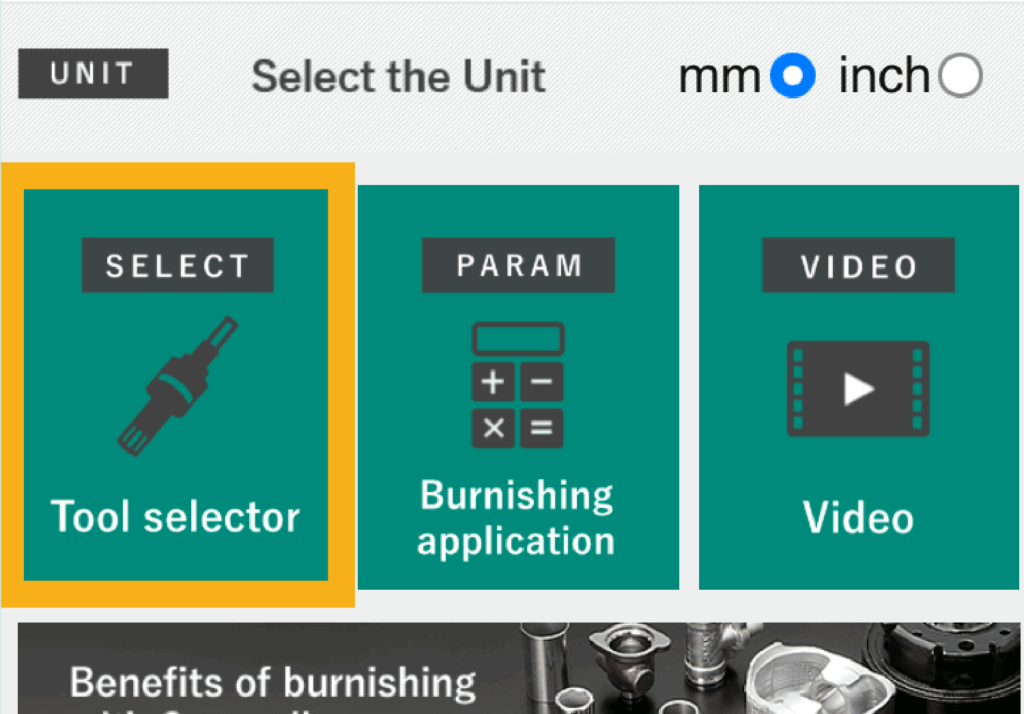

New Ways to Find Burnishing Solutions

We’re always implementing new ways for you to find answers and guidance quickly. If you’re looking to find the right Superoll roller burnishing option, try our:

Superoll Selector App (click to try)

And, get your top roller burnishing questions answered here:

Superoll FAQs

Testing Services – The Best Way to Explore our Technologies

Our High Pressure Water Jet Deburring testing process is designed to show you exactly how the JCC systems can meet your cycle times and cleanliness specs. Testing takes places in our Wixom Technology Facility. Learn more about parts testing here:

Testing is available for Cavitation Abrasive Surface Finishing (CASF), a process ideal for post-processing additively manufactured components. CASF effectively removes build structures and smooths complex geometries on castings used in aerospace, automotive, and nuclear applications.

Looking for a replacement for Discontinued Kinechek® hydraulic speed regulators?

We can help you determine the right model from Sugino’s Hydro-Speed regulators or assist with similar options.

Get Expert Help with all of Sugino’s Technologies

Key Takeaways

- Sugino highlights innovations in precision cleaning, deburring, tooling, and surface finishing for 2025.

- New solutions include the JCC 4+1 Deburring System for complex angles and a Jet Deburring Machine operating at 10,000 PSI.

- The RDM-S robot deburring cell automates processes to enhance efficiency and reduce manual labor costs.

- Innovative parts washing units like the Jet Storm Washer and modular JCC-Module integrate easily into existing lines.

- Sugino introduces advanced machining units and testing services to showcase their high-pressure water jet and finishing technologies.