How to Choose the Best Fit for Precision Deburring and Productivity

Every machined part ends up with burrs. These unwanted metal protrusions can affect function, quality, and safety. But not all deburring methods are created equal, and the choice you make affects throughput, consistency, labor cost, and your ability to scale.

In this guide, we break down the most common methods from manual finishing to advanced automated techniques, and help you see where machine-driven automation delivers repeatable precision with less labor risk and greater throughput.

BEST FOR

Typical Result

Manual Labor

Automation Fit

Manual Deburring

Low volume, prototypes

Inconsistent, high variation

Rotary Tool

Part features

Faster than hand deburring

Moderate

Manual vs. Machine-Based Methods

Manual deburring — whether with files, hand wheels, or bench tools — reliably delivers variable results because it depends on individual skill and judgment. Even the most experienced operators deliver inconsistent finishes on different shifts or parts.

Modern manufacturing demands repeatability, throughput, and predictable quality — attributes that are difficult to achieve through hand finishing. That’s where machine-based and automated approaches excel: they turn deburring into a controlled, measurable process with less reliance on operator skill.

A Look at Deburring Methods

Thermal Deburring

Fuel gas and oxygen are combusted under pressure. The resulting explosion incinerates the burr into oxidized powder.

Chemical Deburring

Micro-burrs are dissolved using a phosphoric acid-based or sulfuric/fluorine-based solution.

Mechanical Deburring

Cutting, grinding, milling, or brushing tools remove burrs through direct contact.

Water Jet Deburring

Rotary Tool

Deburrs by a rotating tool with a special protruded edge. This can be made more efficient by mounting on a machining center or CNC lathe.

Belt Polishing

Different Methods of Float Deburring

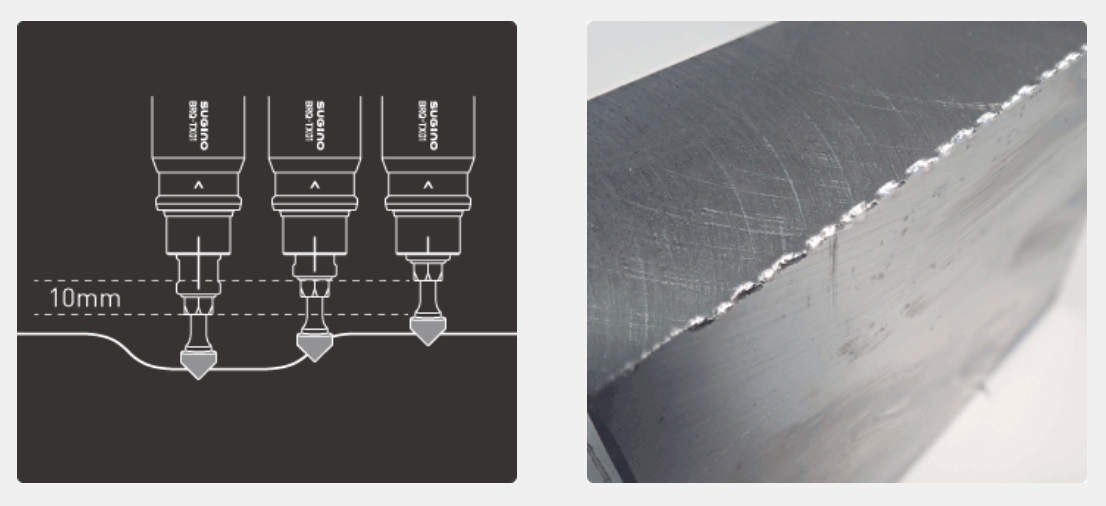

AXIALLY FLOATING TYPE

The axially floating type utilizes a mechanism that extends and retracts in the Z direction. It is ideal for deburring the edges of workpieces and is often used to deburr the contours of castings, and burrs that remain after machining.

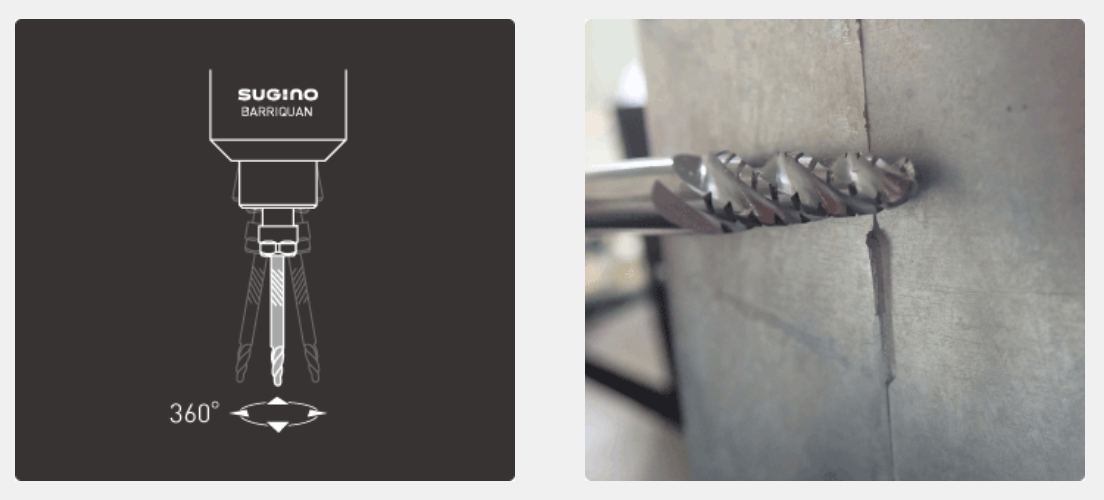

TILTING FLOATING TYPE

With this type, the tool is tilted to the workpiece. Suitable for protrusions and burrs that occur on the "surface" rather than the edge of a workpiece. It is often used for parting line removal of aluminum die castings, etc., and is mainly suitable for deburring using robots.

See If Automated Deburring Fits Your Parts →

Explore model types, options, and see what may work for your process.

More ways to learn about deburring automation:

Why Float Deburring Works When Manual Doesn't

Consistent Results Without Operator Dependency

The floating mechanism allows the tool to move axially and/or radially, maintaining uniform contact pressure. This prevents over-cutting, missed burrs, and excessive material removal. Each part receives the same finish regardless of batch size.

Designed for Automation, Not Hand Finishing

Lock in predictable performance, shorter setup times, and repeatable results across production runs. In a machining center, or in a stand-alone cell that utilizes a light payload robot.

Scales with Your Production

Once programmed, the system runs continuously, freeing skilled labor for higher-value machining tasks while increasing throughput and consistency.

- Skill-dependent results

- Variable quality

- Difficult to scale

- Labor-intensive and costly

AUTOMATED DEBURRING

- Repeatable, controlled process

- Consistent edge quality

- Scales with production demand

- Reduces labor dependency

More Than a Tool: A Process Solution

Sugino doesn’t just supply deburring equipment. We help machine shops:

-

Evaluate parts for automation feasibility

-

Test deburring processes before investment

-

Design repeatable, production-ready solutions

-

Reduce risk when transitioning away from manual work

Our goal is simple: help you remove deburring as a bottleneck—not add complexity.